Vibration & Environmental Testing of Electric Vehicle Parts: Ensuring Reliability in the EV Era

As electric vehicles continue to transform the

automotive landscape, the expectations placed on their

components have never been higher. From high-voltage

battery packs to power electronics and lightweight

structural parts, EV systems must operate safely and

reliably under a wide range of environmental and

mechanical stress conditions. This is where vibration and

environmental testing becomes essential.

In the EV industry, testing isn’t just a regulatory

requirement—it’s a crucial step in guaranteeing safety,

longevity, and performance in real-world driving

conditions

Why vibration and Environmental testing Is Critical for EV

Components

Unlike internal combustion engine (ICE) vehicles, EVs

introduce new challenges:

- Higher continuous vibration loads from electric

motors and reduced damping in lightweight

chassis.

- Thermal sensitivity of high-voltage systems and

lithium-ion batteries

- Moisture, dust, and chemical exposure that can

affect electronic components.

- Fast-charging cycles and regenerative braking that

generate temperature swings and mechanical

strain.

testing helps manufacturers identify weaknesses early,

prevent field failures, and achieve compliance with

automotive standards such as ISO 16750, SAE J2380, IEC

60068, and UN/ECE R100.

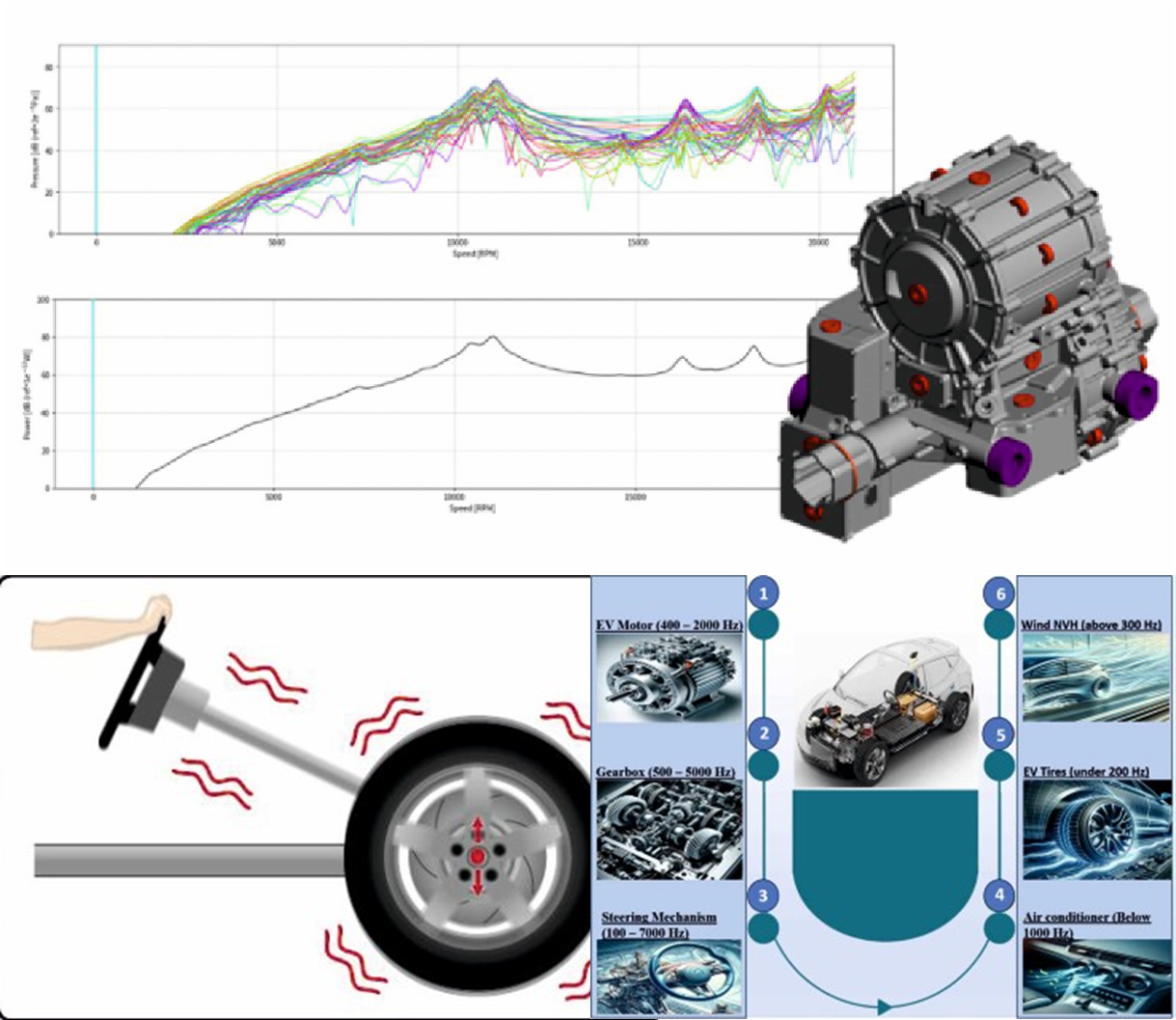

1. vibration testing: Simulating Real-World Driving Force

EV components experience a wide frequency range of

vibration from road surfaces, drivetrain systems, and

vehicle dynamics. vibration testing re-creates these forces

to evaluate:

- Fatigue and durability

- Mechanical resonance behavior

- Structural integrity under random and sinusoidal

vibration

- Connection stability, solder joint reliability, and

wiring robustness

Common vibration tests for EV parts

- Random vibration Testing

Mirrors real-life conditions such as gravel roads,

potholes, and highway driving.

- Sine Sweep Tests Identifies resonance frequencies that may cause

premature failure.

- Shock Testing Simulates impacts and sudden load changes—for

example, curb strikes or emergency braking.

Components commonly tested

- Battery modules & packs

- ECU, MCU, Clusters

- Inverters and converters

- Electric motors & controllers

- Autonomous driving sensors

- Charging system connectors

- HVAC components

BMS (Battery Management System) electronics

Thorough vibration testing ensures that critical parts

2. Environmental Testing: Exposing EV Parts to the Elements

Environmental testing determines how components

perform under harsh or extreme conditions, helping

manufacturers ensure dependability across global climates.

Key environmental tests

Temperature & Thermal Cycling

Simulates exposure to both hot and cold conditions:

-

- High-temperature operation

- Extreme cold starts

- Rapid thermal transitions (e.g., going from indoor

garages to winter roads)

This is essential for batteries and power electronics, which

can degrade quickly under thermal stress.

Humidity & Corrosion Testing

High humidity and temperature cycles can affect:

-

- Electrical insulation

- Coatings and seals

- Connectors and wiring

Salt-fog and corrosion tests also simulate coastal

environments and road salt exposure.

Ingress Protection (IP) Testing

Ensures EV components are safeguarded from:

-

- Water spray, immersion, or flooding

- Dust, sand, and debris

Typical EV targets include IP67 or IP69K ratings for

battery casings and connectors

Chemical Exposure

Evaluates resistance to fluids such as:

-

- Coolants

- Brake fluids

- Battery electrolytes

- Road cleaning agents

Typical EV targets include IP67 or IP69K

ratings for battery casings and connectors.

Battery Nail Penetration Testing

Assesses how components behave in:

- Physical Abusive conditions

- Impact with sharp objects

- Battery electrolytes

Chemical Exposure

Evaluates resistance to fluids such as:

- Coolants

- Brake fluids

- Battery electrolytes

- Road cleaning agents

3. Testing EV Batteries: The Most Critical Components

Battery packs face some of the harshest testing standards

due to their high energy density. testing includes:

-

- vibration and shock durability

- Thermal runaway resistance

- Thermal cycling and aging

- Drop, crush, and mechanical integrity

- Moisture and ingress protection

- Overcharge and short-circuit robustness

A failure in battery performance is not just

inconvenient—it can be dangerous. Rigorous testing

ensures that batteries remain safe even under severe

conditions.

4. Benefits of Comprehensive vibration & Environmental

testing

-

- Improved safety and compliance with global

regulations

- Reduced warranty claims and field failures

- Enhanced product lifetime and reliability

- Beer customer satisfaction and brand trust

- Optimized design and material selection

In the competitive EV market, robust testing is not

optional—it’s a strategic advantage.

Tests done at ATS Test Labs

At Aanchal Techno Solutions, we are a one stop solution for a wide range of your requirements of Dynamic,

Mechanical, Environmental and telecom tests.

No Comments yet!